The methods discussed in this blog can be applied to the following:

- Floorboards

- Tables

- Sideboards

- Skirting

- Beams

- Interior cladding

- Window frames and sills

- Flat Pack Furniture

What causes pine to go Orange?

Questions around how to make pine lighter or stop it from going orange are one of the most queried topics that we get asked over the phones on a daily basis.

Before we get into the nitty gritty of the techniques and finishes required to get the limed or light rustic look on pine, it’s important to understand the root of what causes pine timber to turn the undesirable orange hues.

Firstly, we need to look at the properties of pine wood. One of the disadvantages of pine as a wood is that it’s resinous as a conifer tree.

There are up to 120 different varieties of pine and all have varying degrees of the resinous property. This needs to be taken into account when choosing a finish. A more resinous pine, such as Pitch Pine, will have a far more pronounced colour. If a white water based dye is used over a new Pitch Pine board, it will yellow. However, if a lighter, less resinous pine such as Spruce is used, the dye won’t discolour at all.

It’s also worth noting that if the boards are more than 10 years old, most of the resins will have escaped or dried, so a good sand should prime the surface nicely.

As the pine wood ages, with the help of UV from the sunlight it tends to turn more of an orange colour. In a similar way, as Oak oxidises with time, it tends to darken to a very dark brown and in some cases, black. Beauty is in the eye of the beholder here, and it is up to the beholder to decide whether they might like the warmer patina or pale modern look.

If you would like to maintain the natural beauty of the pine, and don’t mind the ageing process, we recommend that you use a water based varnish, such as the Liberon Natural Finish Floor Varnish or the Fiddes Premier Wood Varnish. Unlike any wood oils, these water based products won’t make the pinewood more yellow-orange, keeping it the existing tone.

Any oil based varnish or oil has a linseed or tung oil element that accentuates the colour of the wood grain, making the colour pop. On hardwoods, with decorative grain and more muted tones, this is often more desirable. However, for softwoods such as Pine and Redwood, as the grain is more open and absorbs more, the colour can become too vivid for many people’s taste.

It's important to note that all wood reacts differently to stains and finishes so it's recommended to thoroughly test to get a formula which produces the finish you're looking for prior to attempting the entire project.

How do you lighten old orange pine or white wash pine floors and furniture?

We recommend two options to make the pine a bleached, pale colour, without the use of harmful chemicals:

- Palette (water based) Wood dye, overcoated with a quality water based floor varnish

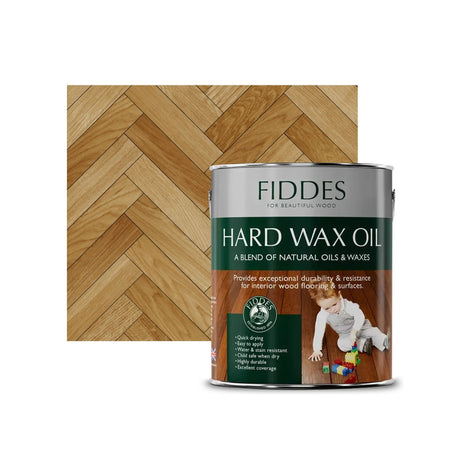

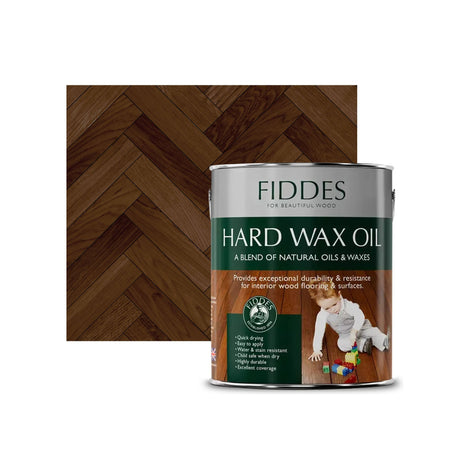

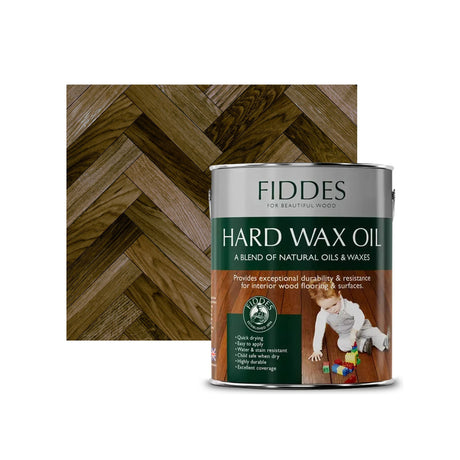

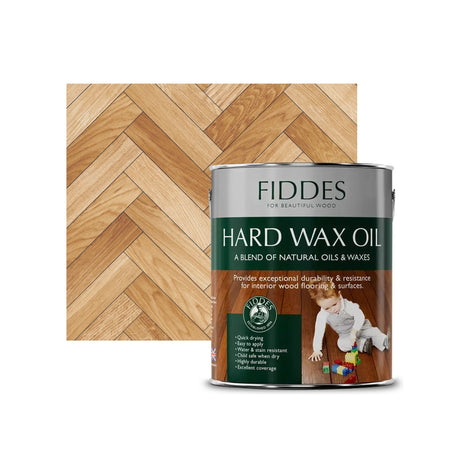

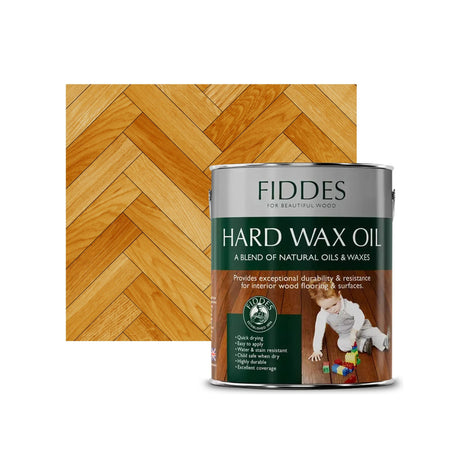

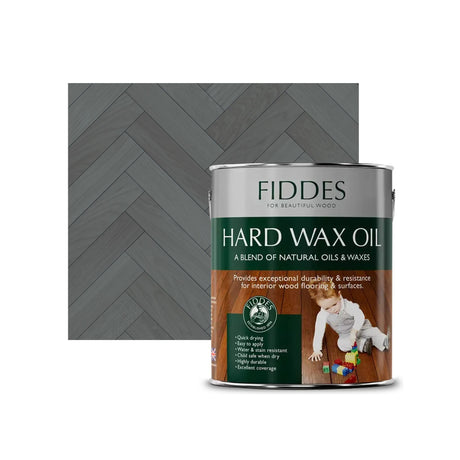

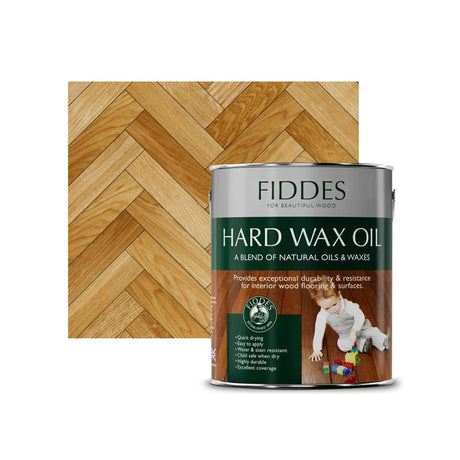

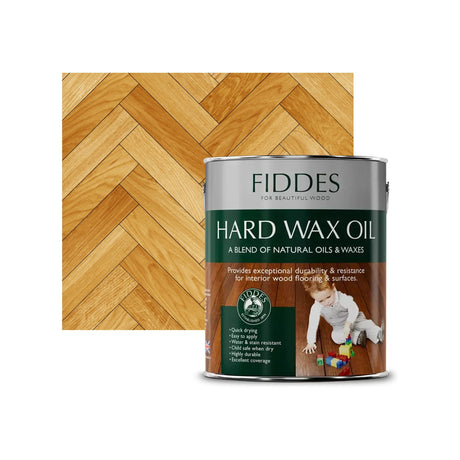

- Use a tinted Hard Wax Oil, such as the Osmo Polyx Raw or Fiddes Hard Wax Oil Natural

Preparation

Caution: If the boards look old and look like they may have had woodworm at some point, be very cautious or even avoid sanding the boards. The little holes are exit points and when you sand the boards you will expose a network of channels which you won’t be able to cover.

The pine will need to be sanded with a P120 to P180 grit sandpaper to fully prepare the wood and take out the aged colour and remove any previous finish. This is important to be done thoroughly before. If the previous finish has not been fully removed it can cause the white stain to look patchy once finished as it will absorb in some parts of the boards and not others.

When applying either a stain, varnish or Hard Wax Oil on a floor or board, it is a common mistake to apply across the board rather than down it. Complete one board at a time and apply with the direction of the wood grain for best results

Option 1)

Best for old or less resinous Pine, such as Spruce

We recommend using the Liberon Palette Wood Dye in white as the stain of choice. It gives a great coverage and even undiluted gives a semi translucent tone over the pine. If you wish to have a more transparent white, you can dilute it easily with water. We would recommend testing this thoroughly before on an off cut or discrete area of the same wood.

Pros:

- Best for old and less resinous pine board

- Uniform coverage tones down the grain colour variance

- Varnish will create barrier against water and UV

- Most likely to prevent discolouration of the pine floorboards or wood over time

- Low VOC (low solvent content)

- Quick drying

Cons

- If the wood dye is diluted, it needs to be carefully measured if a large area is being completed. Inconsistency in dilution can cause a patchy finish

- Knotting shouldn’t be used as it will yellow the knots, hence older pine where the sap has dried or already come out is preferable

- All varnishes can chip which can be difficult to spot repair

Option 2)

Best for newer or more resinous Pine, such as Pitch Pine

If the pine is under 5 years old, it’s important to apply Liberon knotting over any knots before applying oil. This will seal the knots and prevent any seepage of yellow resin as time passes that will discolour the pale finish.

A natural or raw hard wax oil is probably the most straightforward option, but you do need to test and make sure the area is sanded properly prior to application. These hard wax oils have a touch of white pigment to offset the natural yellowing of the oil in the pine wood grain.

Another approach would be to apply a white hard wax oil as an initial coat, wiping the excess off with the grain, to leave the white pigment in the open grain.

After leaving it for 9-12 hours, apply subsequent coat(s) of the natural or raw oil to build the protection. This will give more of a limed effect rather than a white wash. To get the best results with this method it would be best to open up the pine grain with a brass brush so it can capture more of the white pigment.

Pros:

- Great for oily or resinous pines / new pine boards

- Easiest method of application with only 2-3 thin coats required

- Easy to spot repair

- Colour mixed with topcoat

- Most natural finish, texture and sheen

Cons:

- Top up of hard wax oil may be required every couple of years

- 12 hours drying time required between coats

- High VOC (High solvent content)

- May yellow over years, particularly if exposed to extreme sunlight

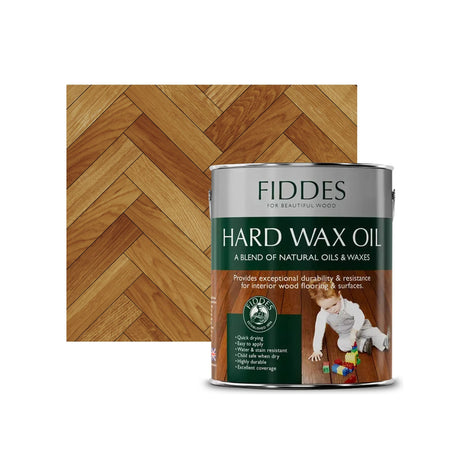

If you wish to achieve a Rustic Brown colour instead of a white pine or a pale pinewood floor, use option 1) but instead test brown shades from the Liberon Palette wood dye range. Colours include Antique Pine, Light Oak or Golden Pine.

You’re probably wondering why we have left our Liming Wax or paste from our recommendations. Pine wood grain, unless heavily worn, is very flat. This means that the liming paste or wax can’t sit in it. Also having a white wax finish on a pale wood floor can trap in the dirt making it look grubby.

As mentioned earlier, staining or colouring wood is a trial and error exercise and not an exact science. Results vary based on the type, age, moisture, and wear of the surface grain being applied to. Hence, it is highly recommended to test on an off cut of the same wood or an inconspicuous area before taking on the whole project.

If you have any questions about this subject or blog, our friendly and knowledgeable team is available to help you Monday to Friday, 8am-5pm. Our email is info@restorate.co.uk and phone number 01285 831668.

2 comments

Hello there. So I have some pine doors. House was built in the 50s and the trim hardwood floors and doors all have the orange glow to them. So far in the kitchen we painted over the trim and installed new floors. But all the bedroom doors need help. We like the wood itself so we don’t want to paint them. But so far we can’t get the pecan brown we are looking for. Any pointers?

Hello I am looking to.buy the corona pine furncher but I want to make the wood a lighter colour what would you recommend? thank you.